CLINCH STANDOFF

SELF CLINCHING THROUGH STANDOFF

📌 Overview

The Stainless Steel Self-Clinching Through Standoff is a precision-engineered fastener designed to create strong, unthreaded spacing or standoff points in sheet metal assemblies. Installed by pressing into ductile sheets, it provides a flush-mounted, permanent fit on one side while allowing clearance or spacing for components, PCBs, or panels.

Made from SS304 (A2) and SS316 (A4) stainless steel, these standoffs deliver outstanding strength, durability, and corrosion resistance, making them ideal for electronics, telecommunications, medical devices, aerospace, and industrial equipment.

✅ Key Highlights

📏 Standard: Available in metric & inch sizes (PEM equivalent)

🔘 Type: Through Standoff (unthreaded for clearance)

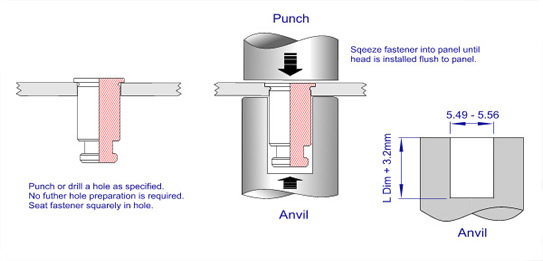

🛠 Installation: Cold-formed press-in method

⚙ Material Grades: Stainless Steel SS304 (A2) / SS316 (A4)

💪 Strength Class: Comparable to A2-70 / A4-70

🌊 Corrosion Resistance: Excellent in outdoor, industrial & marine environments

📦 Size Range: M2 – M6 hole sizes (Lengths: 4 mm – 30 mm)

📊 Technical Specifications

Specification Details Product Type Self-Clinching Through Standoff Material Stainless Steel SS304 / SS316 Style Through (Unthreaded Clearance) Hole Sizes M2 – M6 (metric) / 2-1/56” (inch) Length Range 4 mm – 30 mm Installation Press-in (cold forming into sheet metal) Sheet Thickness From 1.0 mm upwards Surface Finish Natural / Passivated Corrosion Resistance High – rust & oxidation resistant

📍 Applications

✔ PCB Mounting in Electronics & Telecom Devices

✔ Spacing Between Panels, Boards & Covers

✔ Aerospace & Automotive Assemblies

✔ Industrial Machinery & Instrumentation

✔ Medical Equipment & Precision Devices

✔ Consumer Electronics Housing

🏆 Why Choose Our Self-Clinching Through Standoffs?

✨ Permanent & Flush Installation – Secure and neat assembly

✨ Provides Accurate Spacing – Ideal for PCB & component mounting

✨ Strong & Vibration Resistant – Reliable for industrial use

✨ High-Grade Stainless Steel – Resistant to rust, chemicals, and harsh conditions

✨ Available in Various Lengths & Sizes – To suit multiple applications

✨ International Standard Quality – Trusted in electronics & engineering industries

SELF CLINCHING BLIND STANDOFF

📌 Overview

The Stainless Steel Self-Clinching Blind Standoff is a specialized fastener designed to provide strong, permanent spacing or standoff points in sheet metal assemblies where a closed-end design is required. Unlike through standoffs, blind standoffs feature a sealed bottom, preventing the passage of screws, contaminants, or light.

Manufactured from high-quality stainless steel (SS304 / SS316), these standoffs combine exceptional strength, corrosion resistance, and a flush-mounted installation, making them highly suitable for electronics, enclosures, aerospace, medical devices, and precision equipment.

✅ Key Highlights

📏 Standard: Available in metric & inch sizes (PEM equivalent)

🔘 Type: Blind (closed-end design)

🛠 Installation: Cold-formed press-in method

⚙ Material Grades: Stainless Steel SS304 (A2) / SS316 (A4)

💪 Strength Class: Equivalent to A2-70 / A4-70

🌊 Corrosion Resistance: High – reliable in outdoor & marine environments

📦 Size Range: M2 – M6 internal threads (Lengths: 4 mm – 25 mm)

📊 Technical Specifications

Specification Details Product Type Self-Clinching Blind Standoff Material Stainless Steel SS304 / SS316 Style Blind (Closed-End) Thread Sizes M2 – M6 (metric) / UNC/UNF (inch) Length Range 4 mm – 25 mm Installation Press-in (cold forming into sheet metal) Sheet Thickness From 1.0 mm upwards Surface Finish Natural / Passivated Corrosion Resistance Excellent – rust & oxidation resistant

📍 Applications

✔ PCB Mounting where a closed end is required

✔ Prevents screw penetration into sensitive components

✔ Electronics & Telecommunication Devices

✔ Aerospace & Automotive Systems

✔ Medical & Precision Instruments

✔ Industrial Enclosures & Control Panels

🏆 Why Choose Our Self-Clinching Blind Standoffs?

✨ Closed-End Design – Prevents screw pass-through & protects sensitive areas

✨ Permanent & Flush Installation – Strong and clean fastening solution

✨ Vibration & Load Resistant – Secure under dynamic conditions

✨ High-Grade Stainless Steel – Rust & corrosion-resistant for durability

✨ Versatile Sizes – Available in metric & inch thread options

✨ Trusted Quality – Manufactured as per international standards