PEEL BLIND RIVET

Peeled rivets are extremely versatile and necessary for joining softer materials without fracturing or distortions. These are particularly suitable for uneven surfaces or where oversized holes remain after repairs.

PEEL BLIND RIVET

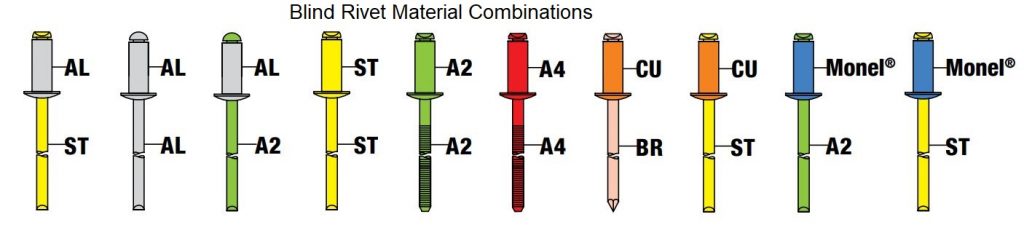

Aluminium Rivets – Lightweight with good corrosion resistance.

Steel Rivets – Stronger than Aluminium with a “flash” coating of Zinc. Low corrosion resistance.

Stainless Steel Rivets A2 – Good Strength and excellent corrosion resistance.

Stainless Steel A4 Rivets – Good Strength and increased corrosion resistance

Copper Rivets – Relatively soft. Excellent corrosion resistance and conductivity.

Monel Rivets – The strongest blind rivet material with excellent corrosion resistance and conductivity. Also excellent high temperature suitability.

GO PEEL Blind Rivets

Peeled rivets are extremely versatile and necessary for joining softer materials without fracturing or distortions. These are particularly suitable for uneven surfaces or where oversized holes remain after repairs.

Characteristics

- Fixing the rivet creates a closing head with a large diameter

- After setting the mandrel head might remain within the rivet body or might drop out

- Especially suitable for connections with wood, hardboard, fibre-glass, plasterboard or similar

- Relatively soft or porous materials can be joined together with high tensile forces

Applications

- Mounting of plastic, rubber, cardboard and felt elements etc.

- Mounting of wooden elements

- Construction of mobile homes

- Fixing of panelling and many others

Blind Rivet Go Peel Dome Head AL-ST E1D59G

Material USAGE GUIDE

Galvanic Corrosion • When dissimilar metals come into contact in the presence of an electrolyte, a galvanic action occurs which corrodes one metal at a faster rate and the other more slowly. This phenomenon can cause major riveted joint failures and care must be taken to avoid the occurrence. The following table is a guide.

| METAL JOINED | |||||

| RIVET MATERIAL↓ | Aluminium | Coated Steel | Stainless Steel | Copper | Brass |

| Aluminium Rivets | YES | CARE | NO | NO | NO |

| Coated Steel Rivets | NO | YES | NO | NO | NO |

| Stainless Steel Rivets | CARE | CARE | YES | YES | YES |

| Copper Rivets | NO | NO | YES | YES | YES |

| Monel Rivets | NO | NO | YES | YES | YES |

| YES | Compatible | ||||

| NO | Incompatible – Avoid contact with each other | ||||

| CARE | Use with care. Painting metals will help | ||||

Hence,

1) Select materials that are as close together as possible in the Galvanic Series Chart

2) Provide a barrier between the two metals, such as paint, non-metallic washer or gaskets

3) Design the fastener as the cathode so the cathodic area is small as compared to the anodic area

4) Use a metallic finish on the fastener that is close on the chart to the mating material