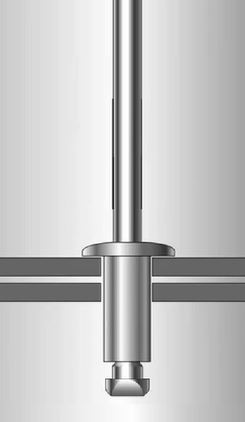

CSK HEAD

General purpose rivet available in a wide range of materials and head styles.

Suitable for applications with normal load bearing requirements.

By far the most commonly used style of blind rivet due to the ease of use and low initial cost.

RIVET BODY

Aluminium Rivets – Lightweight with good corrosion resistance.

Steel Rivets – Stronger than Aluminium with a “flash” coating of Zinc. Low corrosion resistance.

Stainless Steel Rivets A2 – Good Strength and excellent corrosion resistance.

Stainless Steel A4 Rivets – Good Strength and increased corrosion resistance

Copper Rivets – Relatively soft. Excellent corrosion resistance and conductivity.

Monel Rivets – The strongest blind rivet material with excellent corrosion resistance and conductivity. Also excellent high temperature suitability.

CSK HEAD BLIND RIVETS

The Countersunk or CSK head profile provides a neat and flush finish to the joint.

This enables multiple layered assembly and also a safe surface without any projection.

The countersink angle of 120° ensures that this rivet is suitable for thin sheets as well.

Available in many material combinations.

Aluminium – Steel

Blind Rivet CSK Head AL-ST E1D32G

Aluminium – Stainless Steel

Blind Rivet CSK Head AL-SS E8D32G

Steel – Steel

Blind Rivet CSK Head ST-ST A2D32G

Stainless Steel – Stainless Steel

Blind Rivet CSK Head A2-A2 B4D32S

MATERIAL USAGE GUIDE

Galvanic Corrosion • When dissimilar metals come into contact in the presence of an electrolyte, a galvanic action occurs which corrodes one metal at a faster rate and the other more slowly. This phenomenon can cause major riveted joint failures and care must be taken to avoid the occurrence. The following table is a guide.

| METAL JOINED | |||||

| RIVET MATERIAL↓ | Aluminium | Coated Steel | Stainless Steel | Copper | Brass |

| Aluminium Rivets | YES | CARE | NO | NO | NO |

| Coated Steel Rivets | NO | YES | NO | NO | NO |

| Stainless Steel Rivets | CARE | CARE | YES | YES | YES |

| Copper Rivets | NO | NO | YES | YES | YES |

| Monel Rivets | NO | NO | YES | YES | YES |

| YES | Compatible | ||||

| NO | Incompatible – Avoid contact with each other | ||||

| CARE | Use with care. Painting metals will help | ||||

Hence,

1) Select materials that are as close together as possible in the Galvanic Series Chart.

2) Provide a barrier between the two metals, such as paint, non-metallic washer or gaskets.

3) Design the fastener as the cathode so the cathodic area is small as compared to the anodic area.

4) Use a metallic finish on the fastener that is close on the chart to the mating material.