STRUCTURAL BLIND RIVET

Structural Blind Rivets are designed to fix elements where a high resistance to both tensile and shear strengths are required.

STRUCTURAL BLIND RIVET

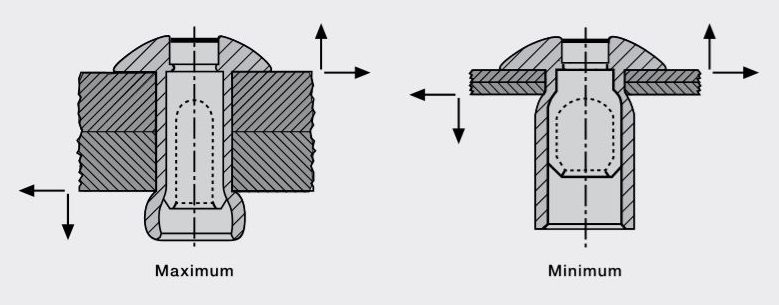

Structural Rivets exceptionally strong once set. The high strength is as a result of the mechanically locked stem. The locking occurs during the riveting process when the mandrel has traveled the full length of the rivet body. The strength comes from the mandrel being locked in place and completely filling the space along the shear plane from the primary through to the secondary side of the head.

When set properly, this results in a flush break, where the mandrel is broken nearly even with the head. Structural Rivets are primarily used in the transportation industries like Truck, Trailer, RV and Locomotive, however it is often used commercially as well.

High Strength Blind Rivets with Conical Closing Head

High Strength Blind Rivets with conical mandrel head provide extra vibration-resistance and a highly strong connection between the elements of varying thicknesses. Solid hole bearing helps to adjust the pre-drilled hole tolerances without any problems. With the proper pre-drilled hole tolerances, these high strength rivets can be watertight. During the setting process, the mandrel head is mechanically locked inside the snap head and the mandrel breaks with the head. The remaining mandrel is retained within the rivet body which allows very high shear and tensile values of these rivets. They are ideal for applications with heavy loads.