Anchor Bolts – Concrete Anchors

Setting a cast-in-place anchor in just the right location can be a daunting task. It’s so difficult, in fact, that post-installed anchors are now becoming the preferred method for attaching wood, steel and cold-formed steel components to concrete instead of cast-in-place anchors.

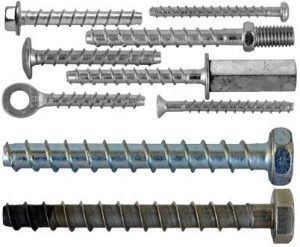

Wedge Anchors

All wedge anchors are for use in solid concrete and consist of an anchor body, expansion clip and a nut and washer. The anchor body is threaded, and can be installed by inserting it into a pre-drilled hole in the concrete where the wedge is expanded by tightening the nut. The hole required for all wedge anchors is equal to the diameter of the wedge anchor being installed. They are also known as stud anchors and throughbolt anchors.

Through Bolt EXG II

- For fixing of heavy objects like steel and wood structures, base plates and brackets in concrete.

- Has fire resistant classification.

- High load capacities.

- Is supplied assembled.

- Long Thread – suitable for stand-of fixing.

- Letter marked head – easy inspection.

- ETA approved in option 7 Available in zinc plated steel.

- SS A4 available on request.

Through Bolt BZ

- For fixing of heavy objects like steel & wood structures, base plates and brackets in cracked & non-cracked concrete.

- High load capacities.

- Supplied as an assembled unit.

- Marking of setting depth.

- Letter marked head for easy inspection.

- Approved in cracked concrete.

- Fire resistant.

- Available in zinc plated.

- SS A4 available on request.

Installation Notes for Wedge Anchors

- Do not Install Wedge Anchors into Green Concrete ( concrete that is less than 28 days old).

- Hole diameter in the item to be fastened must be higher than the diameter of the anchor.

- Holding of the wedge anchor is at one point on the clip only. Length of the anchor is determined by the thickness of the material being fastened. Longer lengths do not provide any extra benefit.

Heavy Duty Anchor

- For fixing of medium to heavy duty applications where extra high degree of load capacity is required in both cracked and non cracked concrete.

- Fire Resistant classification.

- High steel strength.

- Easy installing – through fixing.

- Approved for use in cracked concrete.

- ETA Approved in Option 1.

- Steel zinc plated

Drop In Anchor

- For fixing with metric screws, threaded rods etc of suspended ceilings, structural steel and brackets in concrete

- Use with a setting tool.

- Easy and flush to the wall fixing.

- High load capacity.

- Small drill & setting depth.

- Fixture, screw or threaded rod can be removed without affecting the anchor. Visible control of correct installation: original setting tool leaves four marks in the Drop In Anchor.

- Fire resistant.

Multi Monti

- For fixing of brackets, balcony railings, machines, wood & steel structures etc in cracked and non cracked surfaces and other solid base materials.

- Expansion free, Through fixing.

- Economic & Easy installation – without any special tools.

- Reduction of installation time of upto 50%.

- Torque control not required.

- Fire Resistant

C BOLT with Flange

Expandet C-Bolt with flange for fixings in cracked/ non-cracked concrete and lightweight concrete . It can be used for fixing brackets, balcony railings, machines, wood- and steel structures etc.

Advantages

- Small drill diameter and Expansion free.

- Through fixing.

- Economical and easy to use- without use of special tools.

- Reduction of installation time up to 50%.

- Torque control is not required.

- Can be installed close to edges.

- ETA approved in Option 1, for use in cracked and non-cracked concrete .

- Anchorages can be designed in Expandet Calculation Software.

Concrete Hammer Rivet

Special for fixing of suspended ceilings, ventilation systems, cladding, brackets and sheet metal in concrete.

Advantages

Ceiling Anchor

Special Considerations

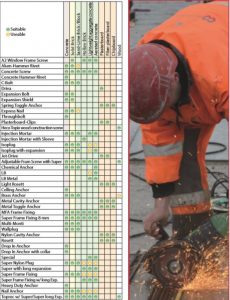

Making the right Anchor Choice for Concrete.

Selecting the correct anchor for an application is not as simple as it may appear. There are actually several factors that affect proper anchor choice, so considering them all is essential.

When choosing a post-installed anchor consider the following main factors.

Environmental conditions

Interior exposure only will require low corrosion resistance whereas a sea-front application is a severe case requiring high corrosion resistance with other applications falling between these extremes.

Building code requirements

Local regulations relating to structural loads will influence the selection of anchor. For example, in case of earthquake regions, anchors suitable for cracked concrete must be considered.

Substrates (what is the anchor being installed into)

The material into which the anchor is being installed into is known as the substrate and includes concrete, lightweight concrete, brick etc.

The manufacturer’s catalogue will have a product selection guide indicating which anchors are most suitable for different substrates.

Anchor configurations

Factors to consider here include how close the anchors will be placed to the edge of the concrete, spacing between anchors, thickness of substrate etc.

Non expansion anchors such as Multi-Monti and Injection Mortar are better suited for close to edge fixing.

Thickness of the concrete should also not be overlooked. The Drop in Anchors are better suited for shallow substrates.

Anchor capacities

For thicker concrete, adhesive anchors will often have better capacity.

You can utilise the design software of the manufacturer to help in selection in this respect.

Job site obstacles that may hamper installation

This is something that may be difficult to predict or control. Consider the following.

- Who will perform the installation?

- Will the holes be drilled properly?

- Are the different workmen able to ensure correct alignment?

- Is a qualified supervisor going to be present during installation?

- Will suitable installation equipment be available?

- Are there any hindrances to proper installation?

Usage Notes

Do not use construction chemicals with mechanical anchors. The expansion clip of wedge anchors requires solid contact with the base material and usage of any chemicals will interfere with the holding of the anchor causing instability and possibly failure at any time.