Spacers and Standoffs

Spacers and Standoffs are two common types of positioning electronic hardware. Look inside an assembled circuit board, and you will be greeted by a bevy of Standoffs and Spacers, because in the world of Electronic Hardware, they are the standard for connecting and mounting circuit boards, panels, doors, and gears providing sturdy support and alignment.

Both are commonly used to properly position parts within an assembly, to reduce component contact, to elevate stacked sections, to ensure enough room for heat to dissipate, and to separate or create space between two objects. These guys are workhorses!

We maintain a ready range of Spacers and Standoffs:

Types

- Male-Female (E.T.) Standoffs

- Through Internal Threaded Standoffs

- Round Un-threaded Spacer

Materials

- Brass

- Brass – Nickel Coated

- Mild Steel

- Stainless Steel

- Nylon

- Nylon with metal Inserts

Standoffs

A standoff is a threaded separator of defined length used to raise one assembly above another.

They are usually round or hex (for wrench tightening), often made of aluminum, brass, or nylon, and come in male-female or female-female forms. In electronics they are frequently used to raise a printed-circuit board above a surface.

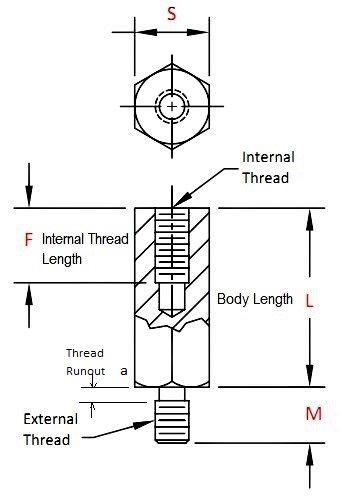

E.T. Spacers [Male-Female Standoffs]

These are Internal-External Threaded Spacers. Standoffs can be round, hexagonal or square in shape. These are Male-Female type.

Our range of Stainless Steel Male-Female Standoffs are made from AISI 303 and on request AISI-316 can be provided.

Standoffs are available in a variety of materials including aluminium, brass, plastic, steel and stainless steel.

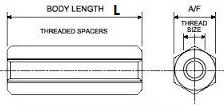

Through Internal Threaded Hex Standoff [Female-Female Standoffs]

These are Internal Threaded Spacers and are available in Brass-Nickel coated, Nylon and Stainless Steel.

Other options on special order.

Suitable for using with screws at both ends providing a clean finish. Nylon Spacers may have metal inserts to provide stronger threads.

These will however be separated by a non conductive material to ensure insulation.

Insulating Standoff – Nylon Standoffs

Insulating standoffs keep two parts from touching each other, thereby preventing electrical shorts. These are made from Nylon.

They may with threads tapped into the Nylon or with metal inserts molded into the Nylon.

Unthreaded Spacers

Spacers are fasteners used to connect, separate, or position parts in assemblies. They provide sturdy support, alignment and spacing to a variety of applications such as circuit board assemblies, panels and doors.

The hollow body of a spacer is designed to allow the shaft of a screw to pass completely through it before entering the surface material. This forces a gap to be kept between the screw head and the material or component below, while still allowing the fastener to be properly torqued.

They are generally installed over the top of screws to space out or stack circuit boards or paneling. Spacers can be stacked to cover longer screws if needed.

They can have a hex or round shape, and are not threaded. They are made of steel, stainless steel, nylon, or aluminum and can have a male or female body style. Also used to calibrate the height of a sensor or switch, or provide heat or electrical isolation.

Round Spacers

Female unthreaded round circuit board spacers do not have threads and resemble a plain, cylindrical tube.

These Round Unthreaded Spacers can be used for separation and insulation as well.

Our range is from 2.5mm to 5mm.

Unthreaded Spacers are available in Nylon and Stainless Steel.

Hex Spacers

Hex spacers resemble Female-Female Standoffs but are unthreaded. The Hexagonal body provides a higher strength and ability to place better on the assembly.

These are available in Black Nylon and provide a sturdy assembly.

Brass Inserts

These solid thread inserts are widely used, most commonly in plastics at the moulding stage. They are used in many moulding processes. Injection Moulding, Compression, GRP, Extrusion Blow Moulding etc. Inserts can either be incorporated at the time of the moulding process, or be inserted as a post moulding operation.

These Press fit inserts are pressed into a component shortly after it has been molded. While the plastic is still warm and pliable, the insert is pushed into the part. When the plastic cools, the insert becomes fixed in place.

Range : M2, M2.5, M3, M4, M5