Dowel Pins

Dowel pins are also referred to as parallel pins and are commonly used to retain parts in a fixed position or to preserve alignment.

Metric DIN 7 parallel dowel pins are solid cylindrical rods made of a variety of materials that are used to strongly and accurately join two or more objects together. Parallel dowel pins are able to join parts together by frictional forces between the pin and material into which it is inserted. In order to keep the assembled parts aligned, the dowel pin must be rigid and fit tightly into the pre-drilled holes of the mating parts.

Features : Ground surface finish , Flat or rounded or chamfered ends.

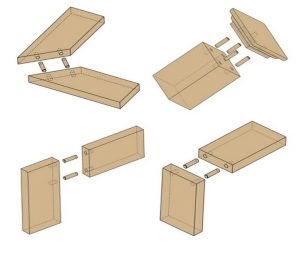

Dowel Pin Operation

Dowel pins do not possess moving or actuated components. Dowel pins’ mechanical capabilities stem from their high coefficient of friction, and any adhesive that may be applied when they are inserted into press-fit predrilled holes. They must be rigid while in use so they are capable of keeping the assembled parts aligned without further hardware fastening. For a firm fit, the hole should be exactly the same size or slightly smaller than the dowel’s diameter. Dowel pins typically have working loads identified, with a breaking strength measured as when a double shear occurs.

For aesthetic applications where the hardware must be accessible or seen, a dowel pin can appear uniform to its assembly–a distinct advantage over other fasteners. For this reason, dowels are commonly used in furniture. They can also be applied as hinges and simple axles.

Material : Hardened Carbon Steel, Stainless Steel AISI 303, AISI-316

Standard : DIN 7 Tolerance m6