Captive Screws

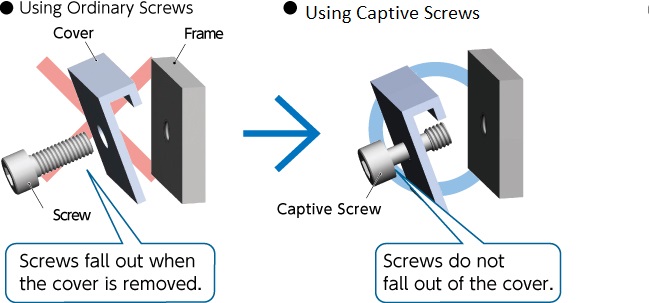

Captive screws basically are specially designed to lock into position in a hole, enabling easy setting up and removing of the attached pieces even without the complete removal of the screw.

A captive screw is designed to prevent this from occurring. It can freely rotate within the first component, with some axial movement, but it’s unable to separate from it.

USES : Captive screws are used when fasteners must remain attached to equipment, such as in cover panels. They are a requirement for several machinery safety standards.

A conventional screw typically passes through a clearance hole in one part and then screws into a threaded hole in a second part — so the first part is clamped to the second.

However, when the fastener is unscrewed from the threaded hole in the second component, it can easily separate from the first one.

They provide a secure joining, and avoid fastener loss or damage that might be caused by a loose part.

Captive screws come with Philips, Allen head or standard heads that are designed for usage with drill equipment and ordinary screwdrivers. Captive screws can be found in several configurations and sizes much like the conventional screws premeditated to be utilized for large number of applications.

Material : Stainless Steel AISI-304 , SS-316 on special order.

Size Range : M2 to M6 in ready stocks

Installation of Captive Screws

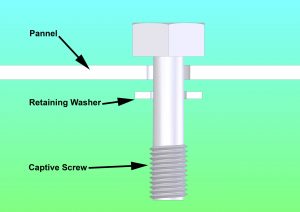

Using a retaining washer

To install a captive screw on a panel using a retaining washer, the screw is first passed through a hole in the panel. The washer is then screwed onto the captive screw, until the reduced diameter section is reached, retaining the screw on the panel.

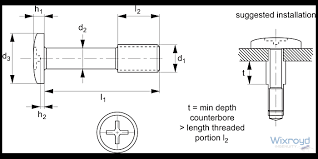

Using a retaining flange

To install a captive screw using a retaining flange, the flange is first pressed onto the panel. The captive screw is then screwed into the flange until the reduced diameter section is reached and the screw is retained.