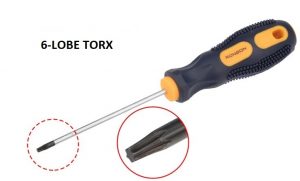

Torx MC Screws 6-Lobe

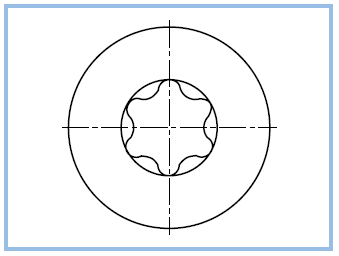

Hexalobular socket according to ISO 10664

The notion of a drive with hexalobular sockets are a decisive step in developing drives better adapted to manual and automated assembly. This drive is becoming increasingly popular throughout the world.

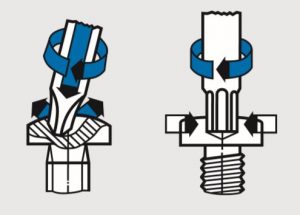

Compared to drives like cross recesses and conventional hexagon sockets, this system is characterized by a lower risk of deterioration and a lower pressure force requirement. The typical «cam out» slipping of the tool has hence been eliminated and the force transmission improved.

The general dimensions are given in the product information of the respective catalogue group.

Our Trilobular screws use the Torx Compatible drive for reliability and ease of installation.

The Torx compatible drive is a reliable method of fixing screws. This drive can take more torque and does not slip.

The hexalobular socket screw drive uses a star-shaped recess in the fastener with six rounded points.

It was designed to permit increased torque transfer from the driver to the bit compared to other drive systems. This system features a 15-degree drive angle which provides high torque transfer. Radial forces are drastically reduced resulting in longer tool life. It has vertical sidewalls which increases tool engagement CAMOUT is defined as the force upward on a screwdriver as the torsional force is increased to tighten the screw.

Torx Screws do not have camout problems as no camout forces are created to push the driver up and out of the fastener recess. Due to this, the pressure required to keep the screwdriver in the socket reduces significantly and therefore reduces operator muscular stress and fatigue.

Because of these advantages, Torx drive screws are very popular in the automotive and electronics industries. This is also the preferred drive for our range of UltraSlim screws.

Available in a number of head and body options.

PAN head style which permits better holding.

- Manufactured as per ISO 14583

- Our range of TX PAN head screws is presently in Stainless Steel.

- Grades AISI-304 and AISI-316

- Size Range : M1.6 to M10 up to 150mm length

- Finish : Passivated. Black Oxide coating on special orders

Countersunk Screws are used where a flush finish is required

- Our range of TX CSK head screws is presently in Stainless Steel.

- Standard – ISO 14583

- Materials: AISI-304 AISI-3166

- Size Range: M1.6 to M10 up to 150mm length

Dome Head as per ISO 7380-1

Also known as Button head Screw. This provides a lower profile fixing and is visually appealing.

6-Lobe Socket Head Cap Screws as per DIN 912

This is a very useful screw form that provides a very reliable fixing for machine construction.

Flanged Button Head 6-Lobe (TORX)

Made as per ISO 7380-2, this is extremely useful to provide a low profile fixing in slotted holes and softer materials.

Drive Bits available for these screws.