Safety & Conical Spring Washers

These are used for locking a device and reducing the vibration. They reduce loosening by preventing unscrewing rotation of the fastening device; locking washers are usually also spring washers.

Washers are available in a wide range such as spring washers, star washers, multi-tooth washers, disc spring washers, wave washers, taper washers, safety washers etc.

Serrated Safety Washers Type S – Schnorr Type

The Safety Washers are of trapezoidal cross section and serrated on both sides. The security is achieved through friction and mechanical locking.

Advantages

- The cross section ensures locking effect at the outside diameter.

- Due to the closed ring form, high degree of pretensioning is achieved.

- Sliding surfaces allow tightening with damaging the mating surfaces.

- High resistance to vibration due to positive locking of the serrations

- Suitable for a wide range of screw/bolt heads minimizing stocks.

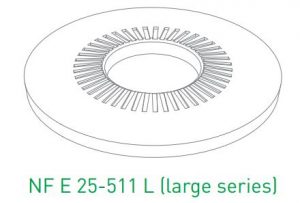

Afnor Contact Lock Washers – NF E-25 511

Contact Washers are Conical shaped Lock Washers formed with a ribbed top surface. The conical shape exerts locking force 360 degree around the underside of the screw head/ nut by generating tension. The ribbed top surface further enhances the locking force and resists the torqued fastener connection potential for loosening under pressure and vibration. This is a single-sided toothed and non-slip locking washer, providing the designer the ability to secure wobble-prone screw effectively. It is particularly suitable for use on slot fasteners, dynamic cross-loaded to the screw connections and applications that require high biasing forces.

These washers are widely used in locomotives, appliances, elevators, electrical towers, medical machinery and electronic equipment.

Afnor Contact Lock Washers NF E-25 511 AISI 304 A2 –

Afnor Contact Lock Washers NF E-25 511 AISI 316 A4 –

Range available : Sizes – M3 to M20

Materials : SS-304 / SS-316. As per NFE – 25511

Type M – Recommended for use with Hex head Screws and Bolts.

Type S – Recommended for use with Cylindrical head screws (Allen Screws) and CHS, PAN Screws.

Type L – Recommended for use with oval bores and soft underlying surfaces (Aluminium and Plastic materials etc.)