Solid Rivets

A solid rivet has a manufactured head on one end and a solid shank on the other. Solid fasteners offer cheap but efficient alternative in various assembly operations.

Their USP lies in their low cost and lightweight feature for industrial operations involving welding and movable joints. Being lightweight, large quantities can be transported over large distance without adding to the overhead production costs

Choosing the right solid rivet with the suitable head is important. It depends on the usage and the visibility factor. We are stocking various types of heads and sizes in solid rivets. Common head styles are round, countersunk, flat, button, universal, oval, truss, pan etc. Please contact us for any further clarifications

These are available in Stainless Steel as our default range.

Dome or Round Head

CSK

Flat Head

Flat Head

Hammer Drive Rivet Type U

This rivet is formed in one piece and consists of a body having a helical thread, performing a deformation in the support where it is introduced.The visible round head secures relatively thin parts in all support.

U-drive rivets (also known as hammer drive screws or ) are unslotted round head self tapping rivets often used for attaching nameplates in castings and for sealing drain holes in corrosion proofing tubular structures.

They possess multiple start threads with large helical angles and an unthreaded pilot point.

Similar to nails they are driven into mating parts with a mallet or hammer for a quick and permanent assembly. No tapped threads are required in the mating part.

However, the u-drive screw must be of harder material than the mating part and a undersized pre-drilled pilot hole is required.

The assembly can be done in a blind hole.

Drilling support and drilling piece to be fixed. The assembly is done manually with traditional tools (hammer, mallet or small hand press).

Used a lot for name plate of label fixing on metal bodies. That is why they are also known as name plate rivets.

Usage Guide

Select correct Rivet Size.

Rivet Diameter – Remember that material distortion is likely if the rivet diameter is more than 5.5 times the thinnest material of the joint.

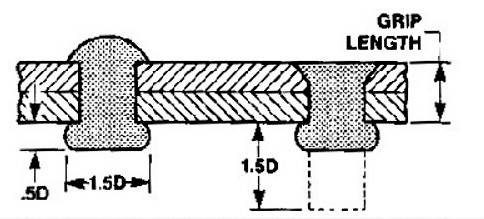

The length of the rivet is very important. The rivet length protruding through the joint should be 1.5 times the rivet diameter. If the rivet length protruding through the material of the joint is more than 1.5 times its diameter, and especially if the setting forces are not perfectly axial, the rivet shank will tend to bend over rather than deform concentrically

When the rivet has been set, the shop head should have a diameter of 1.5 the original rivet diameter, and its depth should be at least .5 times the rivet diameter.

Installation

- Line Up Pieces. Before you get to the installation of the rivets themselves you will need to line up the two pieces that you want to join together.

- Mark Rivet Holes.

- Drill Rivet Holes.

- Insert Rivets into Hole.

- Use Air Hammer.

- Repeat Process.

- Check Fit.

Rivet Failure Causes

- Rivet “dumped.” If the rivet length protruding through the material of the joint is more than 1.5 times its diameter, and especially if the setting forces are not perfectly axial, the rivet shank will tend to bend over rather than deform concentrically.

- Rivet driven at a slant. If the forces applied to the rivet during setting are not axial the material pieces of the joint will tend to move relative to each other.

- Space between materials of the joint. Clamping forces must be applied to the joint during the setting process. Any space between joint materials will allow a swelling to occur in the rivet at this location, and the joint will lose its frictional shear component of the joint strength.

- Damaged rivet head or material due to the rivet gun set being allowed to “come-away” from the rivet during the setting process.