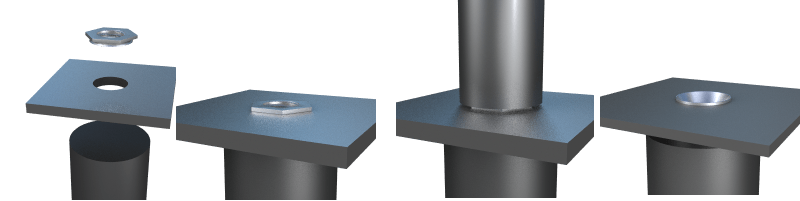

Flush Nuts

If you have a need for an industrial fastener that, after installation, will be completely flush with its surrounding surface, then the self-clinching flush nut should be your fastener of choice.

This type of insert nuts for flush insertion on both sides are flush with the top and bottom of the sheet metal.

These fasteners are ideal for applications where a thin sheet requires load-bearing threads but still must remain smooth, with no protrusions on either surface. This can provide strong threads in places which would be inaccessible for installation after chassis are formed.

Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on both sides of the panel. The hexagonal head ensures high axial and torsional strength.

Advantages

- Ease of installation : All that is required to successfully install the nut is a simple parallel press device which can be used to push the flush nut into position.

- Suitable for use in thin metal : Provides a strong attachment in metal as thin as 1.6mm with a FLUSH finish.

- No hole preparation required : Eliminates the need for deburring or refinishing.

- Material suitability : Self-clinching flush nuts can be used in a wide variety of materials, including materials that are not conducive to welding.

- No secondary operations : Eliminates the need for additional tapping after installation.

- Insertion automation : Insertion process may be fully automated, thereby increasing process speed and reducing overall production costs.

- These Type F self-clinching nuts particularly can be installed flush before bending or forming operations get under way without risking potential interference problems that protruding fasteners could cause down the line.

Like all self-clinching fasteners they are installed using a parallel squeezing action, so require access to both sides of the panel.