Spring Pins

A spring pin is a mechanical fastener that secures the position of two or more parts of a machine relative to each other. Spring pins have a body diameter which is larger than the hole diameter, and a chamfer on either one or both ends to facilitate starting the pin into the hole. The spring action of the pin allows it to compress as it assumes the diameter of the hole. The force exerted by the pin against the hole wall retains it in the hole, therefore a spring pin is considered a self retaining fastener.

Slotted Dowel pins or Spring dowel pins can be used to assemble parts without screws. Spring dowel pins do not require threads.

They are shock absorbing and also vibration resistant when compared to normal dowel pins.

Spring pins can be used for many jobs, including electrical connectors in circuits, terminals, actuators, wire harness fixtures, studs, hinges, fixing pulleys or gears to shafts, and more.

They permit a wider tolerance than drive pins, taper pins, or collar pins because of their greater flexibility to retain part in a fixed position or to preserve alignment.

Made from AISI 301 grade of stainless steel as per DIN 1481 our range starts from 1 mm.

Spring Dowel ISO 8752 AISI 301 –

Spring Dowels [Slotted Pins] DIN 1481 ISO 8752 AISI 301

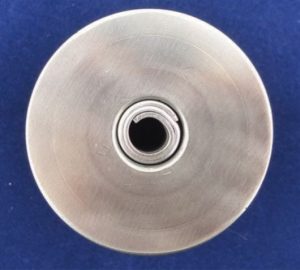

A coiled spring pin, also known as a spiral pin, is a self retaining engineered fastener manufactured by roll forming metal strip into a spiral cross section of 2 1/4 coils. Coiled spring pins have a body diameter larger than the recommended hole diameter and chamfer on both ends to facilitate starting the pin into the hole, the spring action of the pin allows it to compress as it assumes the diameter of the hole.

When spiral dowels are installed, the compression starts at the outer edge and moves through the coils toward the center. Coiled pins continue to flex after insertion when a load is applied to the pin thus providing excellent performance to counter fatigue in dynamic applications.

Spiral Dowel Pins DIN 7343 ISO 8750 AISI 301

These are used extensively in cosmetic cases, automotive door handles and locks, and latches as hinge pins. They are also used as pivots and axles, for alignment and stopping, to fasten multiple components together—such as a gear and shaft—and even as ejector pins to remove motherboards from PCs. The automotive and electrical industries use coiled pins in such products as steering boxes and columns, pumps, electric motors and circuit breakers. Available in Stainless Steel AISI 301 Grade