Clinch Nuts

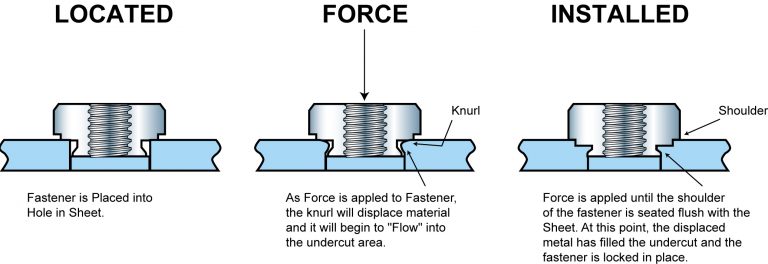

Self-clinching nuts are installed by placing them in properly sized holes in sheets and applying a parallel squeezing force to the head of the nut.

The sheet metal surrounding the head cold flows into an undercut thereby making the fastener an integral part of the sheet.

Clinch Nuts can also be used instead of tapped holes for a more durable and stronger connection. Nuts, standoffs and studs can be used where it is not practical, or possible, to insert a fastener on both sides of a case.

For example, in an instance where there is a nut installed on the inside of an enclosure, you wouldn’t be able to hold a wrench to attach the cover, since the cover would interfere.

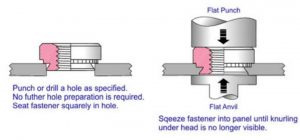

For the best dimensional accuracy we recommend that all holes in the sheet metal application be punched. To install the fastener into the punched Hole a profiled punch is required. It is essential that the recommended Hole tolerances be observed.

Self-Clinching Nuts provide strong reusable female threads in panels that are too thin to be conventionally tapped. Utilising a special proven clinch feature, this fastener has excellent torque-out and push-out characteristics whilst providing a flush finish on the underside of the panel.

Like all self clinching fasteners they are installed using a parallel squeezing force so require access to both sides of the panel.

Available in the following materials

Mild Steel Zinc Plated Metric Download Datasheet

Mild Steel Zinc Plated Unified Coarse Download Datasheet

Mild Steel Zinc Plated Unified Fine Download Datasheet

Stainless Steel SS-304 Metric Download Datasheet

Stainless Steel SS-304 Unified Coarse Download Datasheet

Stainless Steel SS-304 Unified Fine Download Datasheet

Stainless Steel SPL for Stainless Steel Sheets Download Datasheet

Installation Notes

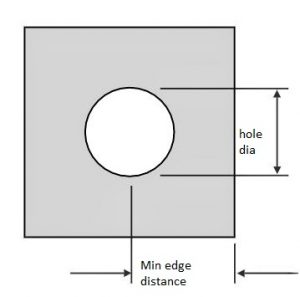

- Determine the location hole using the catalogue/product data sheets

- Do not countersink or deburr punched and drilled holes, the burr makes the press-in process easier.

- In the case of punched holes, the entry side of the punch is preferable for mounting

- Press in the self-clinching fastener (do not hit the fastener with a hammer!)

- In order to avoid deformation of the sheet edge, observe minimum edge distances according to catalogue/product data sheets

- DON’T over-squeeze. It will crush the head, distort threads, and buckle the sheet. Be certain to determine optimum installation force by test prior to production runs.

- Do NOT attempt to insert fastener with a hammer blow under any circumstances. A hammer blow won’t permit the sheet metal to flow into the back tapered shank.

- The self-clinching fastener must always be harder than the component to be fastened. Please observe the information in the product datasheets.

- When using aluminium sheets, make sure to install the steel and stainless steel press-fit fasteners only after anodising the sheet

- Do not install screw in the head side of the fastener. Install from opposite side so that the fastener load is toward the sheet.

- Do not install the nut on pre-painted side of sheet.

Special Note For Installing Into Stainless Steel Sheets

- One of the very basics of self-clinching is that the fastener must be harder than the host sheet. Only then will the fastener perform as intended.

- This is particularly challenging when installing fasteners into stainless steel sheet metal. If your application requires that the fastener clinches into stainless steel, be sure you use the fasteners specifically designed for this purpose.