Taptite Tri-Lobe Thread Forming Screws

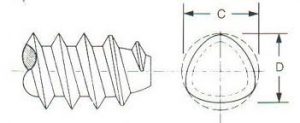

Trilobular Thread Forming System

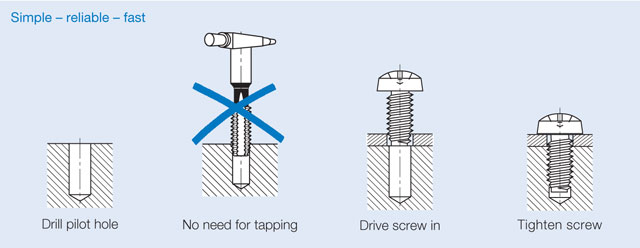

Thread-rolling screws form their nut threads themselves when they are screwed into precut holes. This not only saves assembly and production costs, but also creates stable and secure connections.

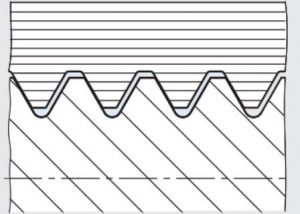

In contrast to thread cutting, the material structure in the mating thread is not interrupted when threading, but compressed and strain hardened. The nut threads are automatically formed in cast blind holes, passages or in drilled, lasered or punched sheet metal parts. Especially suitable for materials such as steel, aluminium, brass or copper.

A trilobular thread forming screw forms a thread with a machine screw’s thread pitch.

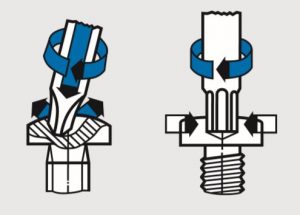

As each lobe of the screw moves through the pilot hole in the nut material, it forms and work hardens the nut thread metal, producing an uninterrupted grain flow.

For use in drilled, punched or cored holes in ductile metals and punch extruded metals without the need for tapping the material thread.

The trilobular thread shape enables the threads to form the internal thread. The screw is designed with a tapered point or commonly referred to as lead threads.

The tapered point allows for lower installation torque during initial thread forming. The trilobular shape is key to allowing the remaining threads to form threads with the lowest amount of installation torque.

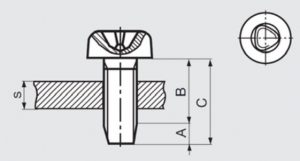

One important thing to note when determining screw length is that the tapered portion of the thread cannot be fully loaded and should not be used to calculate proper screw length.

Advantages

- Thread forming screws form their mating threads eliminating the need for tapping.

- The thread formed is a regular thread (metric or inch), meaning, thread-forming screws can be replaced with conventional screws. May be used in tapped holes as well.

- They provide superior prevailing torque than can be achieved with most locking screws.

- Eliminates chips that result from using thread cutting screws.

- Requires low drive torque and provides excellent resistance to vibrational loosening.

- One of the big benefits is the self-locking effect… because they form their own threads, there are no gaps between male and female threads

Assembly

For the best results, these thread-forming screws should be installed using machinery with torque monitoring capabilities. This could be done using automated fastening systems or by using manual power drivers. These screws can be removed and reinstalled at any time for repairs or service on the application. In the event the thread forming screw is lost during removal, a standard threaded machine screw can be used in its place.

Application Guidelines

Thread-forming displaces material, thus a small bulge is produced at the hole’s entrance. This may prevent parts from being tightly fastened. A 90º chamfer, with a depth of 0.5 to 1 x the thread pitch, will avert that.

A shallow relief bore will do the same. By putting a relief bore at the entrance of the pilot hole, the thread engagement of the individual assembled parts can be kept constant. This way, driving torques can be kept the same, assuming the screw diameter and material are the same.

In thin sheet metals an extruded hole will increase pull-out force.

Since the tightening torques are also dependent on the strength/hardness of the part, core diameter, screw depth and friction coefficients, we recommend you to conduct screw test for determining the optimum tightening torque.

Stainless Steel thread-forming screws are typically used in Aluminium and Non-Ferrous materials.

Our Trilobular screws use the Torx Compatible drive for reliability and ease of installation.

The Torx compatible drive is a reliable method of fixing screws. This drive can take more torque and does not slip.

The hexalobular socket screw drive uses a star-shaped recess in the fastener with six rounded points.

It was designed to permit increased torque transfer from the driver to the bit compared to other drive systems. This system features a 15-degree drive angle which provides high torque transfer. Radial forces are drastically reduced resulting in longer tool life. It has vertical sidewalls which increases tool engagement CAMOUT is defined as the force upward on a screwdriver as the torsional force is increased to tighten the screw.

Torx Screws do not have camout problems as no camout forces are created to push the driver up and out of the fastener recess. Due to this, the pressure required to keep the screwdriver in the socket reduces significantly and therefore reduces operator muscular stress and fatigue.

Because of these advantages, Torx drive screws are very popular in the automotive and electronics industries.

Drive Bits available for these screws.