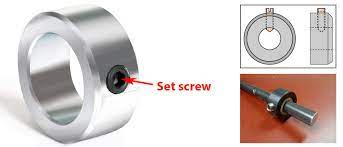

Grub Screw

Socket Set Screw

A set screw is a threaded fastener that normally does not have a head. Unlike most other threaded fasteners it is basically a compression device normally used to generate axial thrust. It is also known as grub screw.

It is used to hold parts like sleeve, collar, coupling, gear etc. on a shaft to prevent relative motion.

The most obvious point of distinction between grub screws and other types of standard screws and bolts is that true grub screws tend not to feature a protruding head. Instead, they’re usually threaded right to the top, and are the same diameter all the way along their length, meaning that the grub screw can be fully driven into its hole to sit flush with (or even countersunk into, depending on the application) the workpiece.

They’re almost always found being used in mechanical systems where two or more metal surfaces rub or press directly together, and where there isn’t room to fit a bolt or other type of protruding head between the two flush surfaces without limiting proper functionality or movement of the part(s).

Socket set screws offer three types of holding power: torsional (resistance to rotation); axial (resistance to lateral movement); and vibrational. Size selection is an important factor in holding power.

Point Selection According to Application

Point of a set screw is that part of the set screw which rotates against the shaft being secured. Point selection is normally determined by the nature of the application. Information on standard point types is as under.

CUP POINT

The cup point is the most used style set screw. It is used for fast, permanent and semi-permanent location of parts on shafts with hardness differential of 10-15 Rockwell C points and where cutting in of cup edge on the shaft is acceptable. It is used for soft materials where high tightening torques are impractical.

Available as PLAIN CUP for soft materials and Knurled cup for resisting more severe vibration.

Knurled Cup or KCP are used for quick and permanent location of gears, collars, pulleys or knobs on shafts.

Standard – DIN 916

Standard – ISO 4029

Flat Point

They are use where parts must be frequently re-set, as it causes little or no damage to part it bears against.

Care must be taken as the bottom threads can deform when the grub screw is tightened which can make disassembly difficult.

Available – DIN 913

Available – ISO 4026

Cone Point

They are used for permanent location of parts. Deep penetration on tightening gives highest axial and holding power.

The pointed tip can either located into a machined depression or it can make and indentation into a softer material. It offers better holding power and increased point pressure.

In material over Rockwell C15 point is spotted to half its length to develop shear strength across point. It is also used for pivots and fine adjustment.

Available – ISO 4027 or DIN 914

Dog Point

They are used for permanent location of one part to another. They have flat end with the threads stopping short of the end.

The tip is normally located into a groove in a shaft and allows the shaft to rotate whilst retaining the part in place.

The end is spotted in hole drilled in shaft or against flat (milled). They often replace dowel pins. Works well against hardened members or hollow tubing.

It is used traditionally to hold one or more objects in place both safely and securely. They are also commonly used in guiding industrial parts into drilled holes.

Available – ISO 4028 or DIN 915

| Set Screw point selection Guide | Plain CUP | Knurled Cup | FLAT | CONE | Dog |

| Permanent hold | YES | YES | YES | YES | |

| High Compression force | |||||

| Vibration resistance | YES | ||||

| Reusable without thread/surface damage | YES | ||||

| Fits well with holes | YES | ||||

| Use as an Adjustion screw | YES | YES | |||

| Use as hanger points | YES | ||||

| Use on hard soft materials. | YES | YES | YES |

Caution

One potential downside of flush-set grub screws, however, is that they can be quite difficult to remove once driven with full force to sit flush with or countersunk into the surface of the workpiece, especially if they do become corroded or the drive slot is damaged due to excessive torque going in. In these sorts of scenarios, grub screws might often need to be drilled out for proper removal, which can be challenging in itself due to the high tensile strengths of materials generally used to manufacture grub and set screws.

Set Screws are not suitable for Tensile loads.

Pro Tip

When drilling a hole for a set screw it is important not to over-drill the hole otherwise you may install the screw too far inside the installation material. Before you begin drilling the hole, measure the set screw against the tip of the drill bit and wrap blue tape around the drill where the screw ends.

This will prevent over-drilling and ensure you have the right depth for the hole. Also make sure to clear out and debris with compressed air prior to installing the set screw.

How to remove a stuck grub screw

As noted above, the process for removing a stuck or bound grub set screw can be challenging – not necessarily more so than standard screws by design, but the fact is that grub screws are very often driven with far higher torque in order to achieve their intended friction-based clamping or binding function. This can make backing them out again tricky under some circumstances.

The basic steps to removing a grub screw will be largely similar to those required for removing any other type of threaded fastener:

- You can apply a penetrating lubricant to help reduce and remove any rust or corrosion present around the threads of the grub screw prior to starting

- Insert the correct kind of drive for the type of grub screw in question, and make sure it is securely seated

- If the screw won’t immediately back out with a counterclockwise torque force, you can attempt to turn the grub screw slightly further right (clockwise), in the direction you’d use to tighten it more – this can often break a rust seal more easily than trying to go directly to backing it out

- If it won’t budge and needs to be drilled out, start by taking an awl or centre punch and using it with a hammer to make a small indentation in the visible end of the grub screw – this will help reduce the risk of the drill bit from slipping or wandering while you drill through the metal

- Choose a suitable diameter drill bit for drilling out the stuck grub screw in question (this will often be specified for different gauges of screw on many screw extractor and drill bit sets).

- Once you’ve drilled the hole, insert the most suitable size of screw extractor into the hole you’ve just made, tap it in with a hammer to ensure a secure fit, then proceed as normal to attempt to turn the extractor counterclockwise using the added torque from a tap-and-die kit handle or similar