Hex Self-Drilling Screws

A Self-Drilling Screw is a Self-Tapping Screw with the added feature of a drill point. The drill point looks a lot like the point of a drill. It will drill a hole and form the mating threads in one operation.

Hex Heads are available in different materials for use in a number of applications.

- Carbon Steel

- Stainless Steel AISI-304

- Stainless Steel AISI-316

Bi-Metal – SS-304 with Carbon Steel Drill point.

Bi-Metal self-drilling tapping screws that provide the corrosion resistance of 300 series stainless steel and the efficiency of drill screws. Such screws avoid the shortcomings of each of these materials.

The whole screw is protected with a silver slide coat. This coating not only adds additional corrosion protection it also reduces the screw in resistance.

This screws can be used for up to two sheets of 1.00mm stainless steel (2.00mm total thickness). The hardened point cuts through the steel then the 304 screws are designed to last a long time without corrosion and can also be used with 316 sheet or cladding. This is a much better option than either a carbon steel screw or a 410 stainless screw that will be at risk of corrosion.

They are suitable for use in both steel and aluminum.

Stainless Steel AISI-410

FINISH/COATING

- Zinc Electroplated

- Class-3 Coating

- Passivated

Special Considerations

Flute Length – The length of the flute determines the thickness of the metal that self-drilling screw can be used on. The flute is designed to extract the drilled material from the hole.

If the flute becomes blocked cutting will stop. Simply put if you have are attaching thick pieces of material together then you will require a self-drilling screw with a flute to match. If the flute becomes blocked and you take no action the drill point will likely overheat and fail.

Drill-Point Material is generally plain carbon steel which is less stable at high temperatures than equivalent high-speed steel (HSS) drill-bits. To reduce wear on the drill point, fasten using a drill motor rather than an impact driver or hammer drill.

High Temperature Stability affects how quickly the drill point fails due to the heat generated by the drilling operation. Refer to the troubleshooting guide at the end of this section for some visual examples.

Drilling Temperature is directly proportional to motor RPM, applied force, and work material hardness. As each value increases, so does the heat generated by the drilling operation.

Reducing Applied Force can increase durability and allow the drill point to penetrate thicker materials (i.e., remove more material before failing due to heat buildup).

Reducing Motor RPM can improve performance in harder materials by allowing the user to push harder during the drilling process and extending the life of the drill point.

CORRECT SETTING OF SCREWS FOR ROOFING

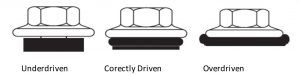

Self Drilling Screws with sealing washers (EPDM Washers) should be tightened only until the washer is depressed firmly enough to provide a weathertight seal.

The Self Drilling Screw should not be over-tightened because this may split the sealing washer or deform the sheet, either of which could lead to water penetration.

You should take particular care when valley fixing because there is no flexibility with the sheet as it is hard against its support.

Take particular care to ensure the fastener is driven perpendicular to the sheeting to avoid deformation of the washer

Caution

It is a common error in assuming that Stainless Steel Self Drilling Screws will drill into steel. However, that is not the case. To provide corrosion resistance, stainless steel self-drill screws are made from AISI-304 or AISI-316 grades. These cannot be hardened and therefore the drill point can only drill into softer materials like Aluminium.

Troubleshooting guide

| Failure Type | Cause of failure |

|---|---|

Flutes chipped |

Excess force used when driving the screw in |

No drilled hole |

Material too hard Driver set to reverse Blunt drill point due to handling or a manufacturer defect |

Flute melted |

Material too hard Too high RPMs used |

Melted point |

Material too hard Excess force used |

Drill bit split |

Excess force used when driving the screw in |