Half Lock Nuts

Are also known as half-thickness nut or a split nut; these are used as a locknut or jam nut.

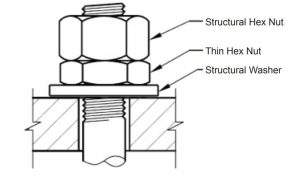

Often used in pairs or in conjunction with a hexagon full nut in a locking arrangement.

- Standards : DIN 439, ISO 4035

- Materials : Mild Steel and Stainless Steel – AISI-304 and AISI-316

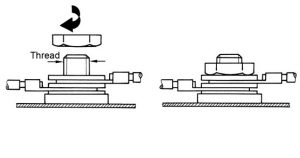

Correct use:

The thin lock nut should be used first and tightened to between 25% to 50% of the overall required torque.

The thin nut is then held in place while the second thicker nut is then installed and tightened to full torque.

Self-Locking Counter Nuts [PAL NUT]

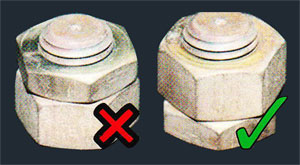

Palnuts are made to DIN 7967 and most commonly referred to as counter nuts, stamped sheet metal check-nuts or self locking counter nuts. Used for axial locking.

These locknuts are made from a spring-like steel which allows them to distort under load pressure, before returning to their original shape in the threaded area.

The Pal Nut is screwed on the bolt on top of an ordinary nut, and has a series of protruding barbs that locks the nut in place when the nut is tightened

They are very lightweight and host a low profile and the ability to be tightened with an internal wrench or fingers.

This provides a vibration resistant locking action whilst remaining usable in small and tricky areas suffering from space restrictions.

These nuts may be used alone for load-carrying in light duty assemblies or they may be used on top of ordinary nuts to assure tightness of high-stress assemblies.

They offer impressive savings over alternative fasteners in initial cost, assembly time, weight and space.

They are removable, reusable, and self-cleaning. They are unaffected by temperatures up to 400 degrees.

DIN-7967 Counter Nut SL SS-304 A2 –

DIN-7967 Counter Nut SL SS-316 A4 –