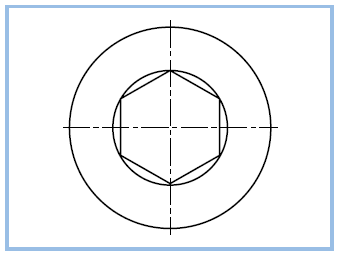

Allen Screws

Hexagon socket Drive

Screws with hexagon socket head have proved their worth in the machine and apparatus construction fields.

The width across flats of hexagon socket head screws is smaller than the WAF of hexagon head screws, permitting more economic design with smaller sizes.

The general dimensions are given in the product information of the respective catalogue group.

Allen Cap SHCS

Socket caps have a small cylindrical head with tall vertical sides. Allen (hex socket) drive is a six-sided recess [Internal Hex Socket] for use with an Allen wrench (hex key). This design is the workhorse of the machine building industry.

The most important reasons for the increasing use of socket head cap screws in industry are safety, reliability and economy. All three reasons are directly traceable to the superior performance of socket screws vs. other fasteners, and that is due to their superior strength and advanced design. Available in full thread and half thread.

Allen Button Head BHCS

The Socket Button Head Screw design is primarily used where a lower profile head is required and for aesthetical reasons.

These screws can take a lower tightening torque as compared to the DIN 912 screws.

Allen CSK

Allen CSK Flat head screws are used for flush mounting of sections, usually where one part slides over another or one part is mounted on another. Flat head screws, like button heads and low heads, are limited by configuration in their tensile strength capability. Because of this, they should not be used in applications requiring full strength, where Socket Head Cap Screws should be used.

Allen Grub Screw

A set screw is a threaded fastener that normally does not have a head. Unlike most other threaded fasteners it is basically a compression device normally used to generate axial thrust. It is also known as grub screw. It is used to hold parts like sleeve, collar, coupling, gear etc. on a shaft to prevent relative motion.

Socket set screws offer three types of holding power : torsional (resistance to rotation); axial (resistance to lateral movement); and vibrational. Size selection is an important factor in holding power.

Point Selection According to Application : Point of a set screw is that part of the set screw which rotates against the shaft being secured. Point selection is normally determined by the nature of the application. Information on standard point types is as under.

Plain cup

The cup point is the most used style set screw. It is used for fast, permanent and semi-permanent location of parts on shafts with hardness differential of 10-15 Rockwell C points and where cutting in of cup edge on the shaft is acceptable. It is used for soft materials where high tightening torques are impractical. DIN 916

Knurled cup

They are used for quick and permanent location of gears, collars, pulleys or knobs on shafts. They resist most severe vibration. Available in ISO 4029

Flat

They are use where parts must be frequently re-set, as it causes little or no damage to part it bears against. Available in ISO 4026 or DIN 913

Cone

They are used for permanent location of parts. Deep penetration on tightening gives highest axial and holding power. In material over Rockwell C15 point is spotted to half its length to develop shear strength across point. It is also used for pivots and fine adjustment. Available in ISO 4027 or DIN 914

Dog

They are used for permanent location of one part to another. They have flat end with the threads stopping short of the end. The end is spotted in hole drilled in shaft or against flat (milled). They often replace dowel pins. Works well against hardened members or hollow tubing. Available in ISO 4028 or DIN 915

Note

The cup point is the most commonly used point style. It is used for the fast permanent or semi-permanent assembly of parts such as collars, pulleys, gears or bearings on shafting of hardness up to within 10 to 15 Rockwell C points of the screw hardness and where the digging in of the point is not undesirable.

Flange Button Head Allen Screw

Low profile head facilitates space saving and safety.

Torx Socket Head Cap Screw ISO14579

This is an improvement on the popular Hex Socket Head Cap Screw. Instead of an Allen drive, the Hexalobular drive or Torx eliminates the few shortcomings of the allen drive. Torx being a slipless drive is also able to take more tightening torque making this an extremely reliable screw option.

Low Head Allen Cap Screw

Low head socket cap screws to Din 7984, often referred to as allen head bolts, have a hexagonal recess and is driven using a hex wrench or insert bit. These are designed to be used in special applications where head height clearance is a problem. Because of their reduced head height and smaller socket size, they normally cannot be preloaded as high as a standard socket head cap screw and should not be subjected to high dynamic loads.

Suitable for use in parts too thin for standard height socket cap screw and for applications with limited clearances