Spring Locking Washers

Spring Washers/ Lock Washers

Spring washers, sometimes called disc springs, are a subtype of washers. They lend their mechanical capabilities to the unique profile of the material: when subject to a load, the irregularities of the washer compress with a proportionate resistance to return to their pre-deflected shape.

Spring washers are employed in applications where assemblies need a part to take up play, eliminate rattle, maintain assembly tension, compensate for expansion or contraction in materials after assembly, or to absorb intermittent shock loads and provide a controlled reaction under dynamic loads.

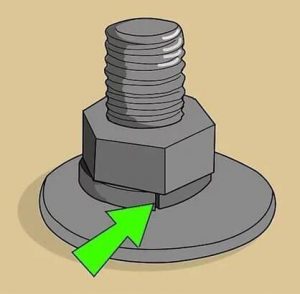

These washers are designed to be tightened to a required torque beneath an ordinary fastener. They exert a spring tension that keeps the fastener from vibrating loose. They are often attached to the nut side of the fastener.

Curved Washer DIN 137A

Curved washers are a type of unthreaded fastener often used to fit around curved surfaces such as the outside diameter of a pipe or tube. Like other washers, they can provide a bearing surface for mating fasteners and are available in a range of materials. Curved washers are excellent for applications with repeated cycles through a range of motion along with a lighter thrust load. The curved washer is often superior to a helical spring for maintaining tension on a cam action or similar application where very little height is available.

Material : SS 301 (useful in spring action)

Split Spring Washers Type A Square

A Spring washer is a metal ring split at one point and bent into a helical shape. This helps the washer to exert a spring force between the fastener’s head and the surface. This keeps the washer firm against the substrate and the bolt thread hard against the nut or substrate thread, creating more friction and resistance to rotation. A spring washer square has square ends at the split end. Provides much better resistance as compared to a plain washer.

Material : Spring Steel, Stainless Steel AISI 304 & 316, Titanium Grade 2.

Split Spring Washers B Flat DIN 127B

The lock washer prevents nuts and bolts from turning, slipping and coming loose because of vibration and torque. Spring Lock Washers are of many types. The most common one being the helical split washer. A ring split at one point and bent into a helical shape. This causes the washer to exert a spring force between the fastener’s head and the substrate, which maintains the washer hard against the substrate and the bolt thread hard against the nut or substrate thread, creating more friction and resistance to rotation.

Materials : Spring Steel, Stainless Steel AISI 301 and AISI 316

Standards : IS 3063, DIN 127B

Size Range : M2 to M48

Star Washers Internal DIN 6797J

Star Washers or Serrated Washers with Internal Teeth. These are locking washers that form part of the serrated or toothed type of washers. They feature serrations or teeth that extend radially inward or outward to bite into the bearing surface.

Material : SS 304/ (SS316 available on request)

Star Washers External DIN 6797A

External Star Lock Washers. Designed for use in providing increased locking force and torsional resistance, these washers are available in stainless steel, plain or zinc plated finishes.

Multi-Tooth Washers

A multi tooth washer increases frictional resistance and suitable for moving parts. The multi tooth lock washer works best with smaller screw heads. It is useful where a good grip is required but the teeth should not be visible as they affect the appearance of the product. Metric DIN 6798 Serrated Lock Washers that are available in Form A (external serrations), Form J (Internal serrations) and Form V (conical for countersunk head screws). The teeth are superimposed on one another maximizing the friction between the surface of the substrate and fastener. The teeth bite into the surface of the substrate to oppose any loosening forces.

Available in Spring Steel and Stainless Steel.

External DIN 6798A

Form A has teeth on the outer edge the washer allowing for maximum

contact on the biggest possible surface area.

Datasheet

Internal DIN 6798J

Form J has teeth that extend inward from the inside edge of the washer and is recommended when the head of the screw is smaller than the diameter washer or when the surface of the fastener is irregular or convex Datasheet

DIN 6798 V

Form V is conical in shape with teeth extending outwards and is used with countersunk head screws with a 90 degree countersink.

Disc Washers – DIN 2093

Non flat washer. They Have a slight conical shape which give the washers a spring characteristic which provide an axial force when deformed.

These are among the most widely used tension generating washers. The washers enhance load or deflection values through stacking.

Material SS 304/ (SS316 available on request)

Conical Spring Washers DIN 6796

Conical washers, also known as contact Belleville washers, hold tight where heat or vibration might shake standard washers loose. Conical washers are known for their ability to provide the highest load bearing capacity and have a low deflection range. Basically, its a conical shell which can be loaded along its axis either statically or dynamically.

Material SS 304/ (SS316 available on request)

Safety Washers “Schnorr” Type

Safety washers were developed as a reliable and economic bolt locking device with the basic principle of a disc spring. This ingenious form combines the advantage of security through friction and mechanical locking. They are in the form of a disc spring but with a trapezoidal cross-section and serrations on both sides. The outer diameter is matched to the head diameter of the pan head and socket head cap screws.

Material SS 304/ (SS316 available on request)

Conical Contact Washers NF-E-25-511[Afnor Washer]

Conical Contact Washer also known as Rib Washer Single Side Serrated Washer as per STD NFE 25-511 and customer requirement. This washer are conical shaped formed with plane mounting side and top serrated side.

The conical shape exerts locking force 360° around the underside of the screw head or nut. The ribbed top surface further enhances the locking force and resists the torqued fastener connection potential for loosening under pressure and vibration. The top serrated side increases locking force and prevent the loosening of bolt during vibration & pressure.

Material SS 304/ (SS316 available on request)